Low Temperature Cu-Cu Direct Bonding

- Low temperature Cu-Cu direct bonding using passivation technology

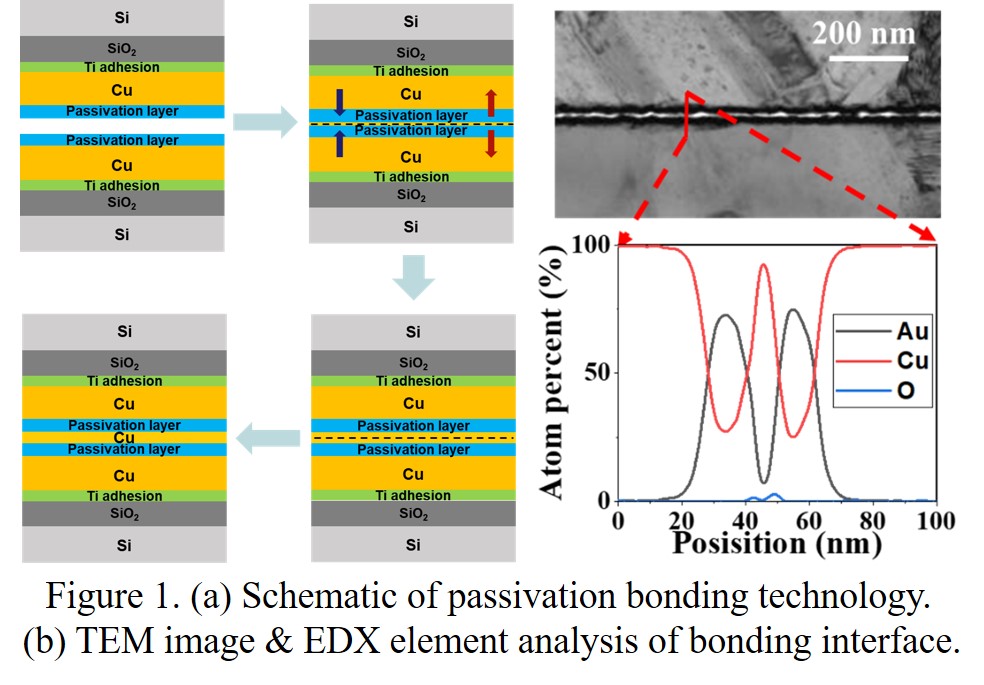

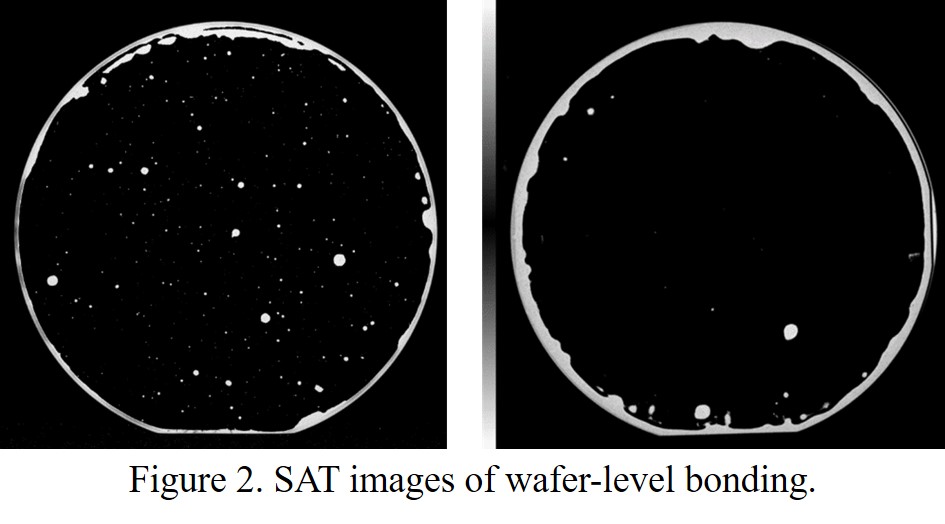

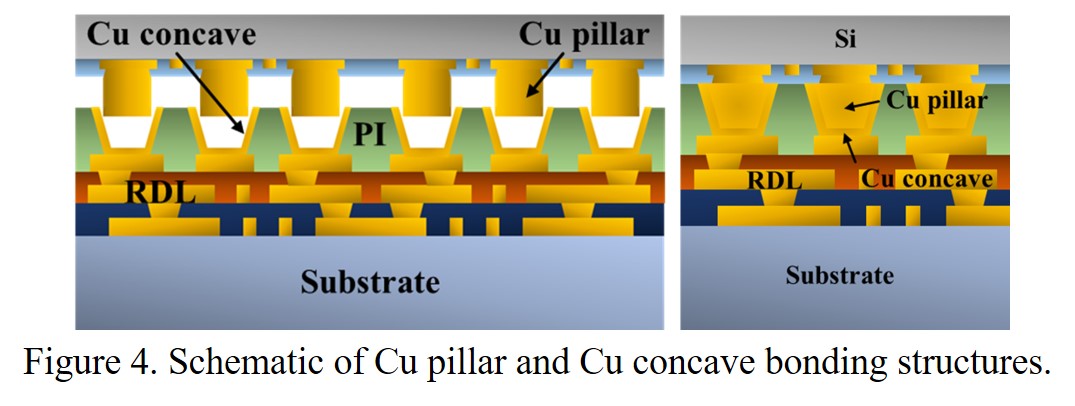

With the development of semiconductor manufacturing technology, the density of transistor increased rapidly. However, the complexity of circuit layout and the delay caused by parasitic capacitance and resistance also exponentially increased. Therefore, delay of metal interconnection has already become the major factor limiting further improvement of IC performance. In order to solve this problem, three-dimension integrated circuit (3DIC) technology has been proposed. With the vertical metal interconnection realized by chip stacking, length of interconnect can be greatly shortened and therefore reduce the delay of parasitic capacitance and resistance. Among the common metal materials used in interconnection, copper, due to its excellent thermal conductivity, electrical resistivity, electromigration resistance and corrosion resistance, become the first choice. However, the copper oxide layer easily forms on the surface under atmospheric condition due to its active chemical property. This oxide layer will greatly increase the temperature and time needed for Cu-Cu direct bonding. Therefore, our team proposed passivation technology, which protects copper surface from oxidation through a thin metal layer with stable chemical property. Accordingly, low temperature copper direct bonding can be realized as shown in Figure 1. In Figure 2, SAT images reveal the high yield of the passivation bonding technology at low bonding temperature. Besides, the results of pull test in Figure 3 also exhibit high bonding strength of this technology. The fraction surface was located on substrate rather than bonding interface in most cases, demonstrating that passivation solution can achieve low temperature Cu-Cu direct bonding with the high bonding quality.

Bonding material : Cu-Cu direct bonding;

Bonding temperature : 70- 180 ℃;

Bonding strength: 8 MPa;

Electrical performance: 10-9–10-7 Ω·cm²;

Pith size : 15 μm;

Reliability performance: Successfully passing thermal cycling test, unbiased highly accelerated stress test.

- Novel Cu pillar-concave structure for low temperature Cu-Cu direct bonding

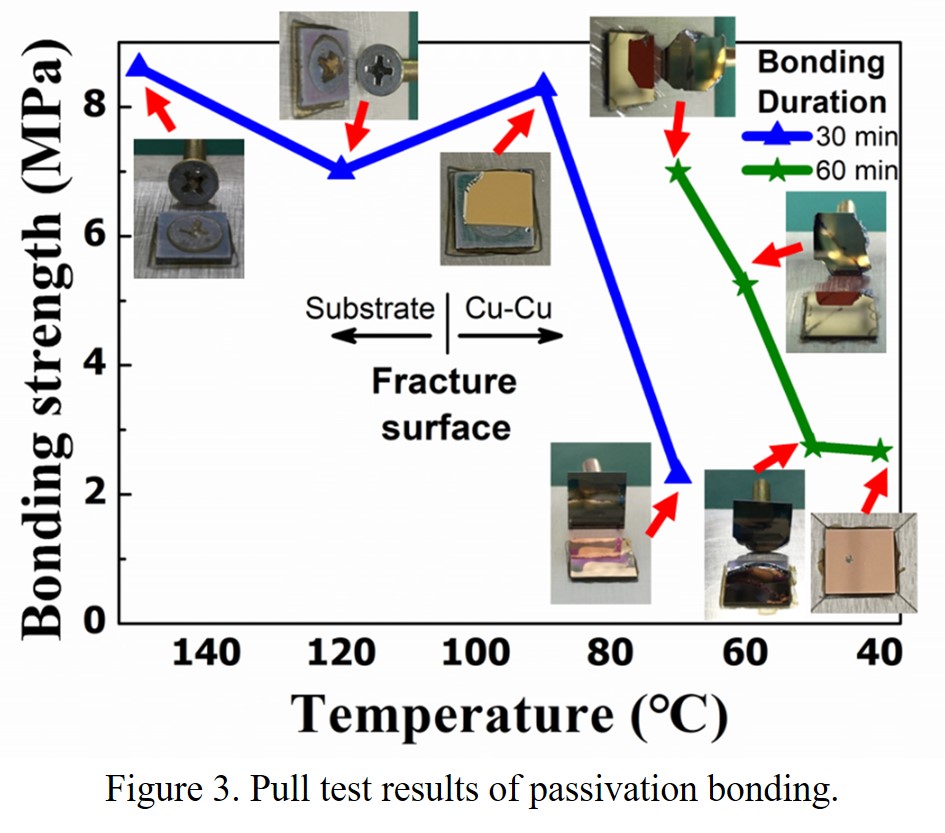

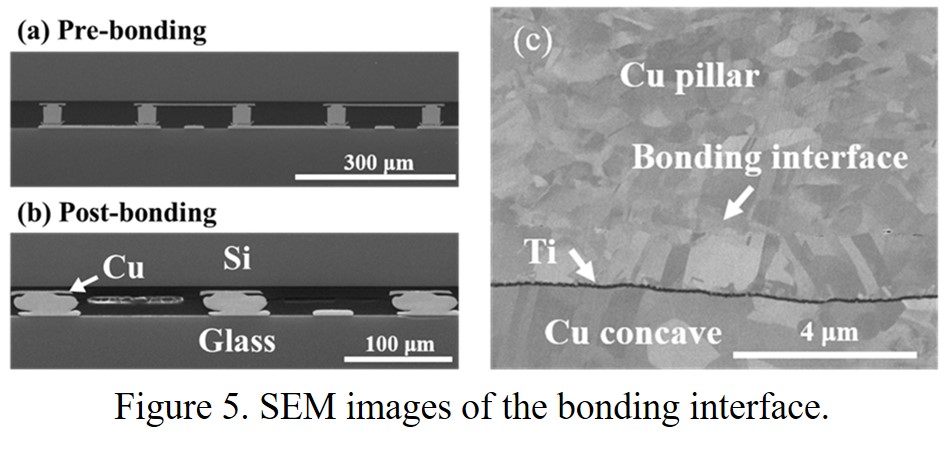

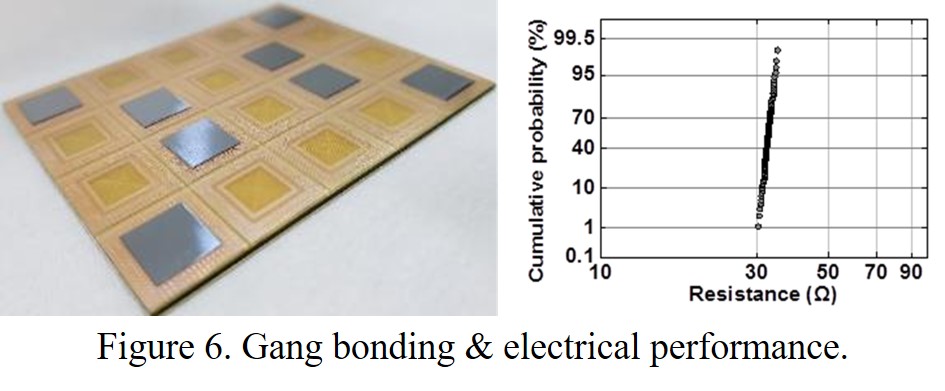

In our research, low-temperature Cu–Cu direct bonding has been successfully demonstrated by the pillar–concave structure as shown in Figure 4. The Cu-Cu bonding mechanism of pillar–concave structure is accomplished through the applied high bonding stress to enhance the diffusion of Cu atoms. The bonding stress of pillar–concave structure was influenced by the sidewall angle of Cu concave. In our research, the sidewall angle of Cu concave was adjusted by tuning parameters of lithography and curing process. The SEM images in Figure 5 exhibit the successful chip level bonding of the pillar-concave structure at 150 ℃ for 1 min. Besides, the pillar concave structure can also be bonded at 190℃ for 20 min by a gang bonding process and demonstrate high electrical performance as shown in Figure 6. This bonding method can provide the high throughput and wide application for 3D IC manufacturing technology.

Bonding material: Cu-Cu direct bonding;

Bonding temperature: 150 ℃;

Bonding strength: 8 MPa;

Pitch size: 15μm;

Reliability performance: Successfully passing thermal cycling test, unbiased highly accelerated stress test.