Cu / Dielectric Hybrid Bonding

Vertical stacking of metals often results in exposure of metallic bonded joints to air, raising reliability concerns. The above issue is often dealt with underfilling approaches, which fills the gaps of metal joints to protect the joints and to increase the bonding strength. However, as the scaling of metal joints moves on, underfill technology encounters difficulties. Therefore, the hybrid bonding techniques, which bonds two materials of metal/dielectric simultaneously, is the key of the next generation bonding technology. Based on the passivation technology, our group has developed a low temperature metal/passivation hybrid bonding technique.

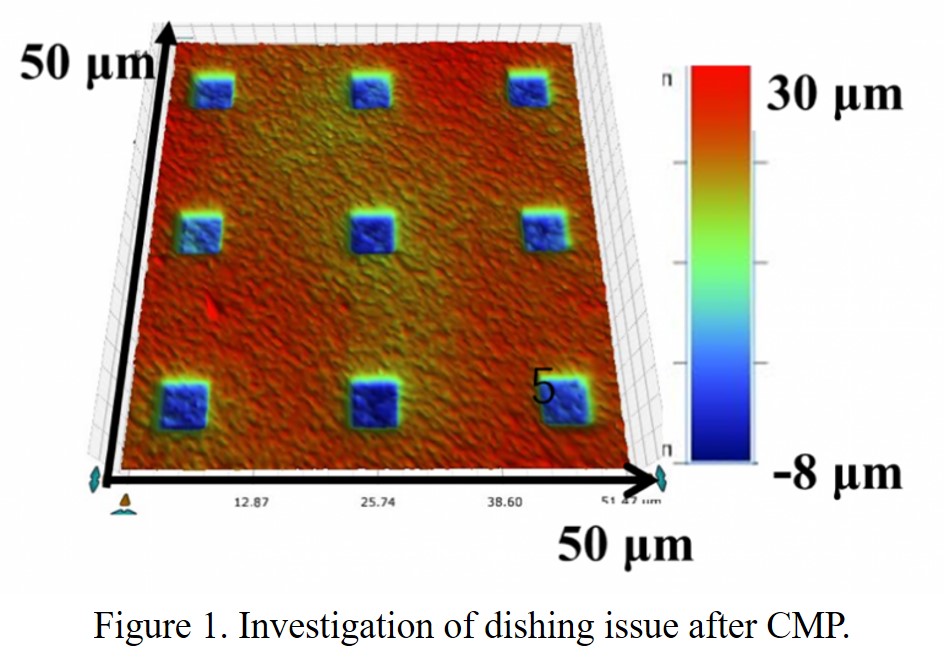

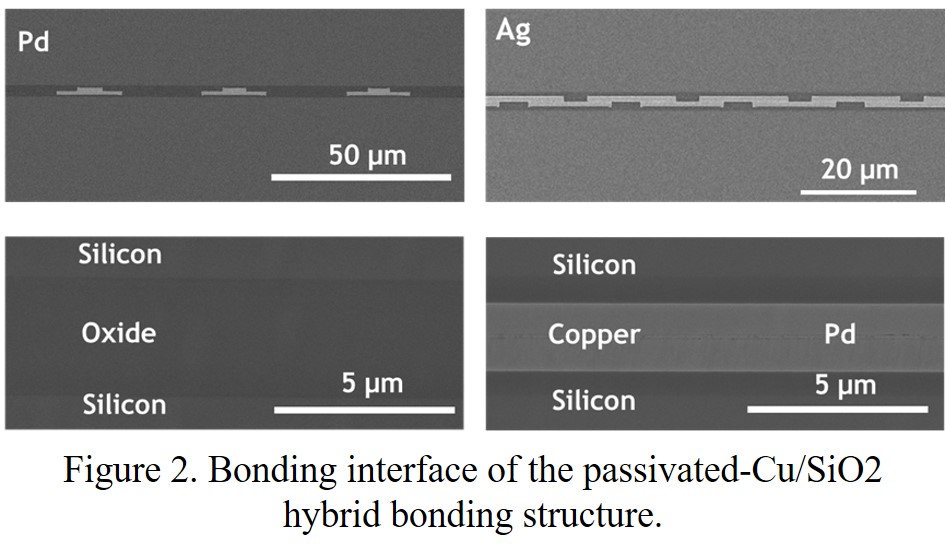

Inorganic materials such as SiO2, SiN or SiCN, can be bonded at low temperature or even at room temperature for the dielectric structure in hybrid bonding. For example, a 120℃ ultra-low temperature Cu/SiO2 hybrid bonding process has been achieved by our group. As shown in Figure 1, passivation material can not only allow low temperature Cu bonding but also fill the dishing caused by the CMP process. By using the passivation technology, Cu/SiO2 structure can be well bonded at low temperatures with a void-free interface as shown in Figure 2. The electrical performance is also excellent with an electrical variation less than 3%. This technology has expanded the application field of 3D-IC and provided a novel solution for heterogeneous integration and advanced packaging technology.

Bonding material: Intermetallic compound (copper-tin)/silicon dioxide

Bonding temperature: 120-180 ℃

Bonding strength: 5 MPa

Electrical performance:10-9–10-7 Ω·cm²

Minimum spacing:5 μm

Reliability performance:Successfully passing thermal cycling test, highly accelerated life test, and electromigration test.