Submicron Cu-Solder Bonding utilizing Ultra-thin Buffer Layers

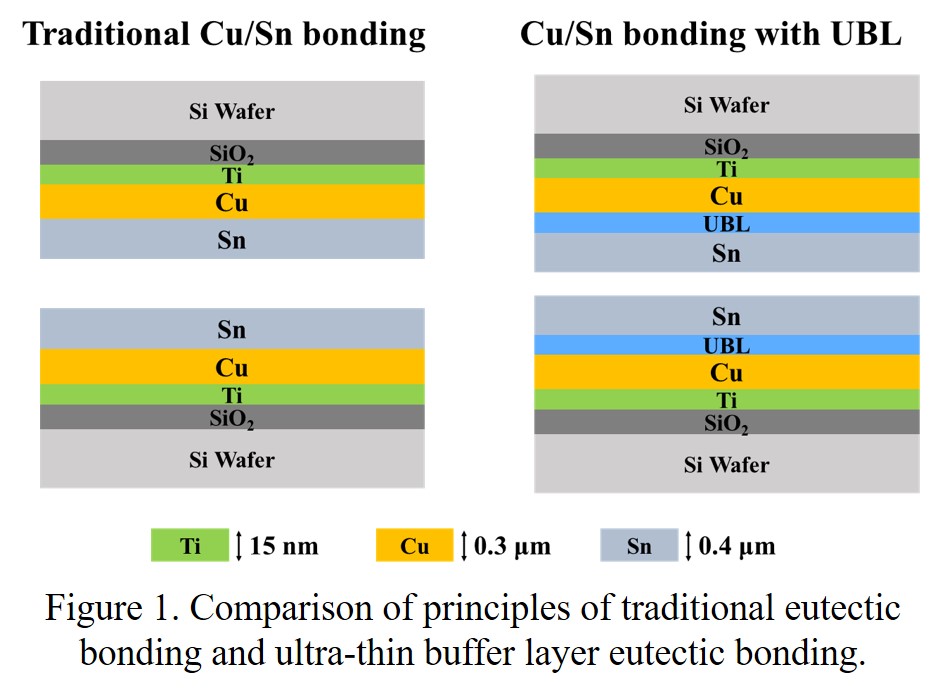

Limited by the rapid interdiffusion of metals, the amount of solder is challenged to be further reduced in the copper/tin bonding structure. Accordingly, as shown in Figure 1, our group has successfully developed the solution of depositing ultra-thin buffer layers to suppress the interdiffusion effect before the eutectic bonding, which can provide bonding of the copper-tin submicron thin film.

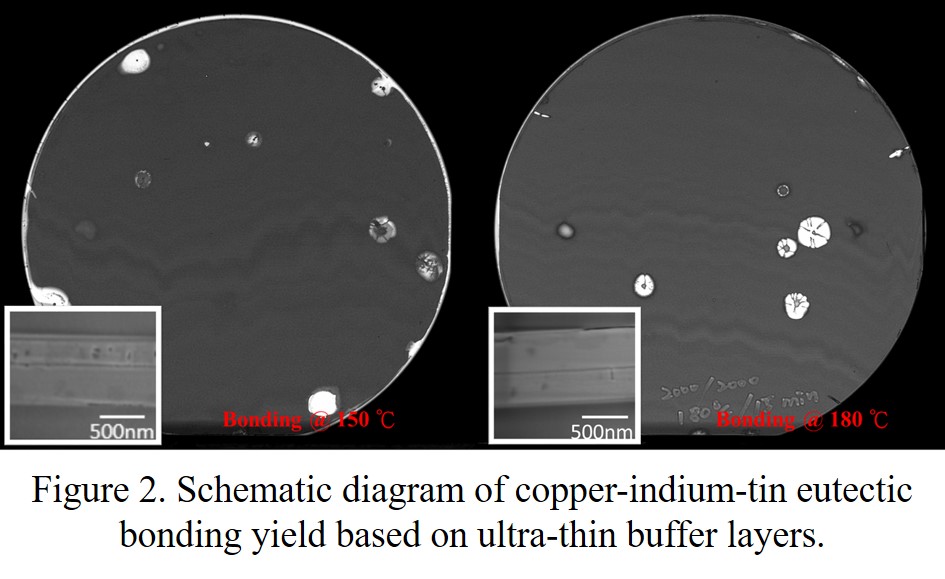

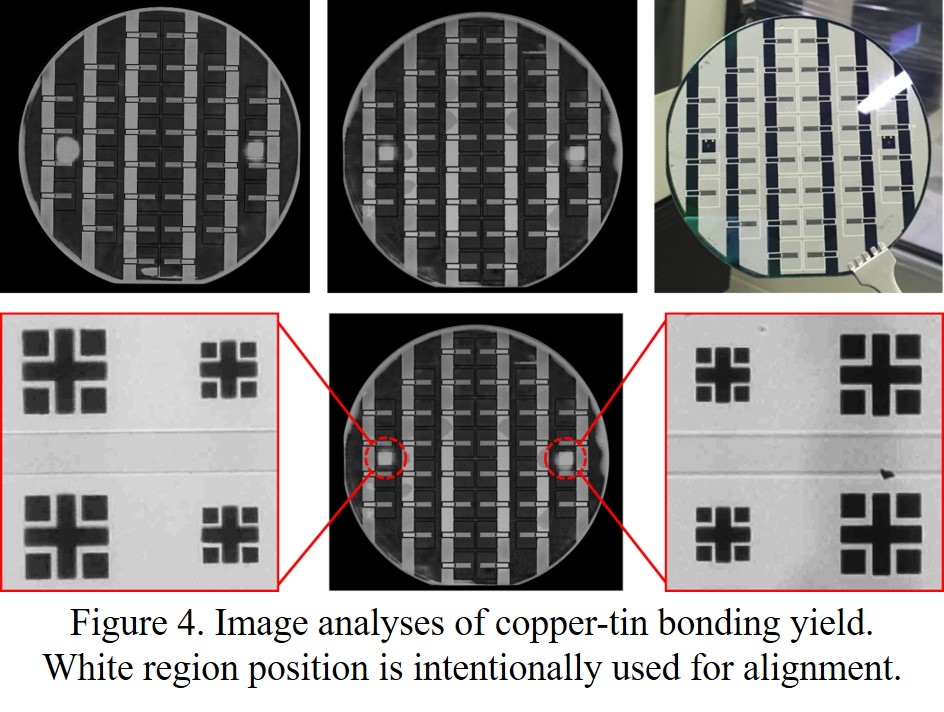

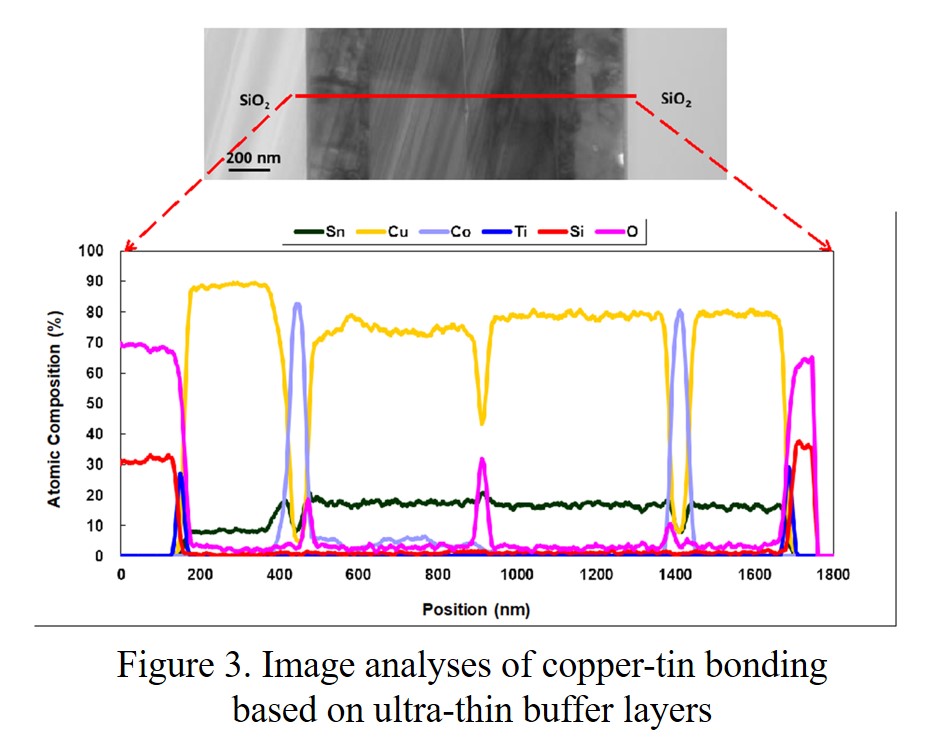

The experimental results exhibit high-quality wafer-level eutectic bonding of copper-tin and copper-indium-tin thin films by using nickel or cobalt as ultra-thin buffer layers, as depicted in Figures 2and 3. The bonding quality has been evaluated by the measurements of bonding strength, as well as a variety of material characterization techniques. Through the electrical performance and reliability tests, excellent wafer-level uniformity, good endurance to high thermal stress and high humidity, were validated. Moreover, as shown in Figure 4, the structure using an ultra-thin buffer layer for asymmetric copper-tin-copper hybrid bonding structure has also been successfully fabricated, demonstrating better reliability characteristic than the symmetrical copper-tin bonding structure.

Bonding material: intermetallic compound (copper-indium-tin);

Bonding temperature: 180-250 ℃;

Bonding strength: 3 MPa;

Electrical performance: 10-7–10-5 Ω·cm²;

Minimum spacing: 50 μm;

Reliability performance: Successfully passing thermal cycle test and highly accelerated life test