Cu / Polymer Hybrid Bonding

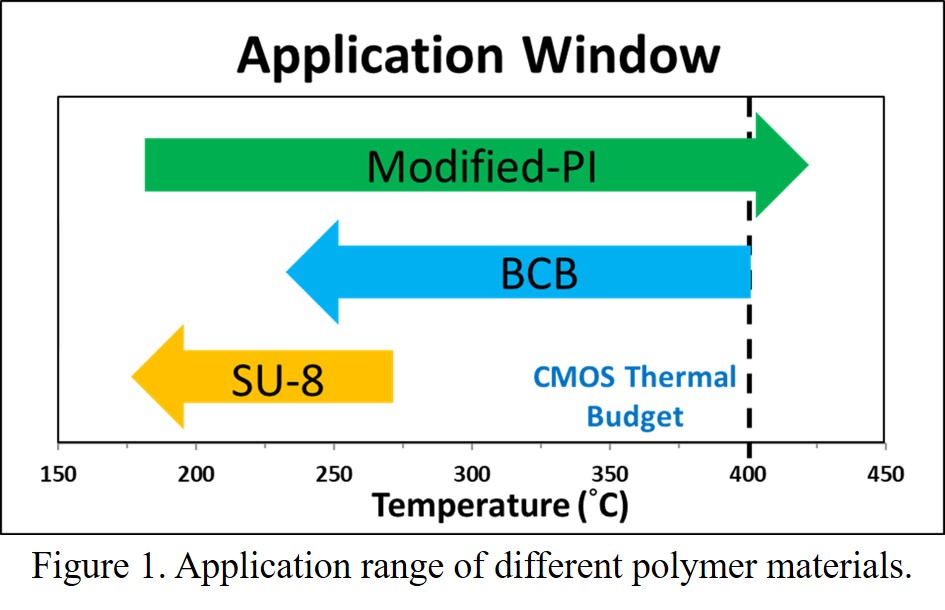

In the hybrid bonding technology, the polymer and metal material are bonded separately at the same time during the bonding process. As shown in Figure 1, traditional polyimide materials are not widely deployed in bonding techniques due to the limits of high curing temperature and high thermal budget. Therefore, our group proposed a low temperature curable polyimide, combined with copper/tin eutectic bonding, which can achieve asymmetric wafer-level hybrid bonding at 250°C. The asymmetric structure can not only effectively optimize the process of metal and polymer, but also realize ultra-thin film bonding technology.

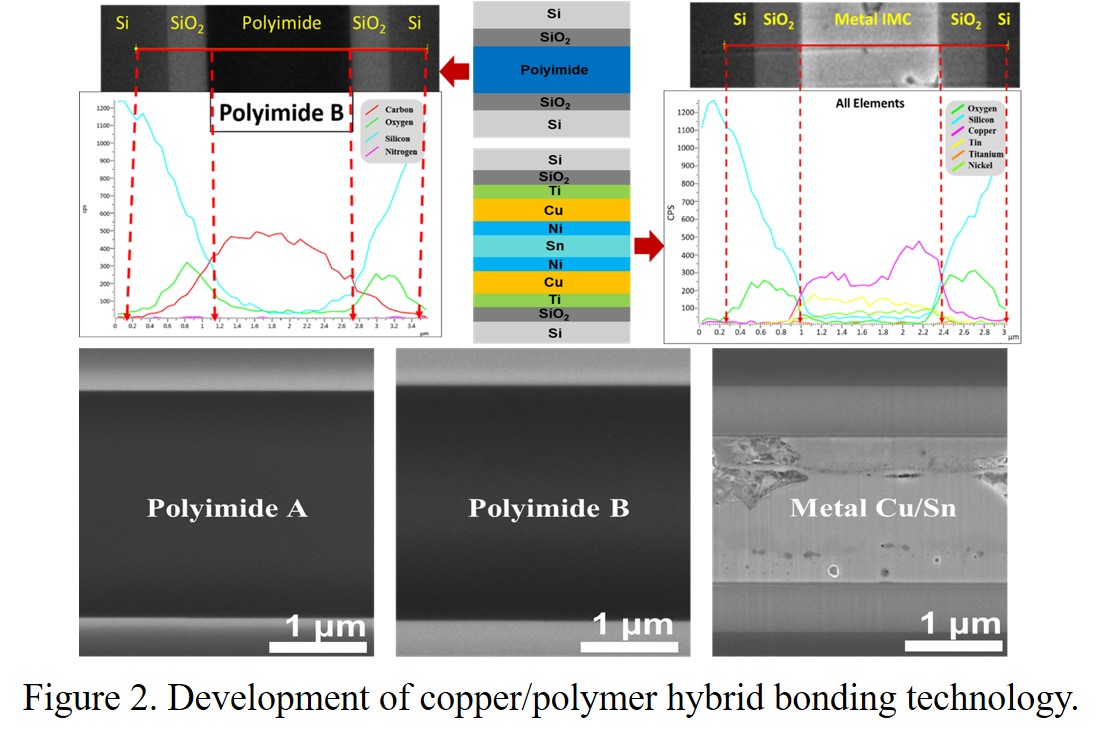

As shown in Figure 2, TEM and SEM images show the good bonding quality utilizing different bonding materials. In addition, a series samples of different polyimide-to-solder thickness ratios were designed in our work to systematically investigate the applicable process range. Under different thickness ratios, the characteristic contact resistance values are all within 10-8–10-7 Ω·cm², and it has successfully passed the reliability test of thermal cycle and high humidity. Based on the above results, this asymmetric hybrid bonding structure has great potential in the future application of 3D heterogenous integration technology.

Bonding material: intermetallic compound (copper-tin) / polymer;

Bonding temperature: 250 ℃;

Bonding strength: 3 MPa;

Electrical performance: 10-8–10-7 Ω·cm²;

Minimum spacing: 50 μm;

Reliability performance: successfully passing thermal cycle test and highly accelerated life test.